China-made Wear Resistance Advantages

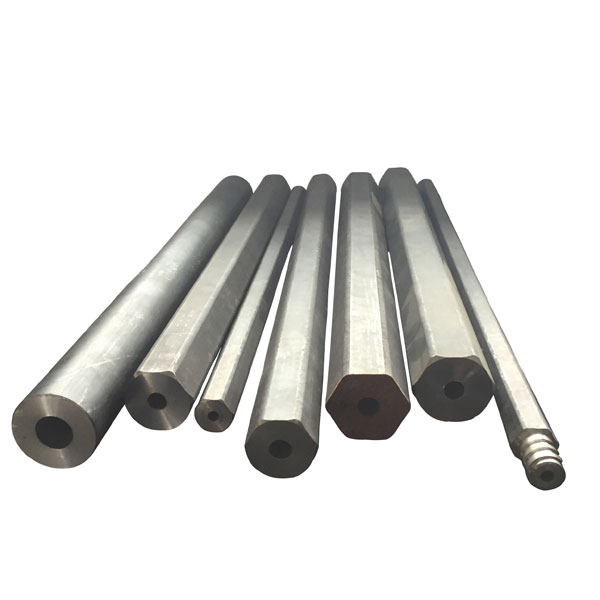

We offer WR-Steel in a wide range of steel grades that can be tailored to your needs. WR-Steel is made as hot-rolled round or flat bar, as tubes, or as grinding media. WR-Steel can also be delivered in more than 680 special profiles in close to net shape. It’s all about helping you optimize your operations.

Over the years, we’ve built a reputation for offering a consistent level of quality to ensure that you get the same high-quality hardening results – batch after batch. Whether you’re making steel ploughs, buckets, rock drilling tools or actually processing the rock, your success is our success.